I just returned from a great trip to China, visiting our manufacturing partners and meeting some of our new suppliers. Since I’m often asked what it is like to make products overseas, I took a bunch of photos to show you. Keep reading for lots of behind-the-scenes goodness on how our products are made.

Like many U.S. companies who manufacture overseas, we use a sourcing company, or agent, who works as a go-between us and the various factories and suppliers. The advantage of this arrangement is that you have someone advocating on your behalf all the time. They also help with cross-cultural understanding, as for anyone who has watched Lost in Translation knows, there are a lot of not insignificant differences between Asian cultures and Western ones.

I totally had an experience just like this!

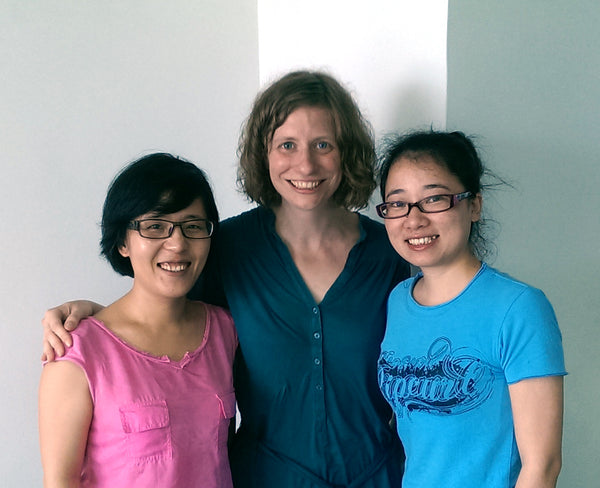

The Po Campo sourcing team consists of Andrew, who is based in Portland, OR and Joanna and Ling in China. Unsurprisingly, given where he is based, Andrew understands the concept of Po Campo very well and helps me communicate some of the brand’s nuances to his Chinese counterparts so they understand what I am looking for. For example, I can say things to him like “I’m looking for hardware that looks durable, but not too ‘North Face-y’,” and he translates that statement into less subjective terms that the team in China can use when sourcing materials for us.

From l-r: Me, Joanna, Andrew. For the more astute Po Campo followers, yes I'm carrying a new handlebar bag prototype.

From l-r: Joanna, Me, Ling

Our factory and suppliers are in the Dongguan area about 1.5 hours west of Hong Kong. It is a large city becoming very cosmopolitan in some areas, but still has a lot of soft goods and plastic manufacturing. It’s important to me to be able to make Po Campo bags in a region where all the raw materials and production facilities are in close proximity to each other because having to ship various materials around the world only increases the product’s carbon footprint. So, not only did I spend a lot of time at the sewing factory, but I also got to visit the suppliers that make our straps, print our fabric, etc. Everything was pretty much within 30 minutes of each other, which was amazing.

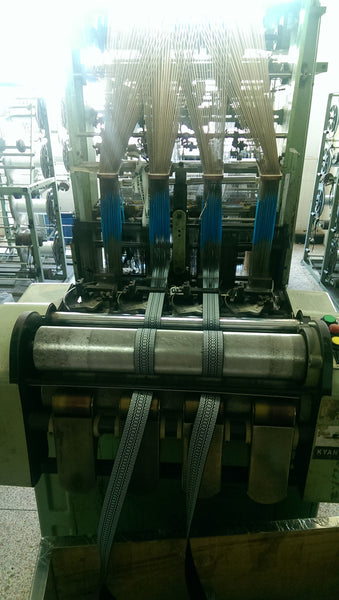

Machine that cranks out webbing, aka bag straps

Visit to fabric printing factory. First the pattern is printed onto paper, and then transferred to fabric with heat to make a more permanent bond. The bottom picture shows the plain white fabric waiting to printed on.

As you can see in the photos below, our sewing factory isn’t huge and doesn’t look much different from the factory we used in Chicago in the old days. The operation spans four floors: Floor 1 is for material cutting and prep, like cutting the straps to the right length; Floor 2 is the sewing floor, in a large room with huge windows for great ventilation; Floor 3 is the sample room where they work with the companies on new designs; and Floor 4 is their warehouse and storage.

The atmosphere feels hardworking, but not terribly intense. My waves and smiles at the employees were cheerfully returned, and we stopped and chatted with several of the people sewing without them seeming concerned that they were going to be reprimanded by a supervisor for taking a break. What I'm trying to tell you here, is that this isn't a sweat factory or a harsh working environment with someone walking around cracking the whip all the time.

Computerized sewing machines for detailed work

The cutting die. As you can see, there is very little waste, which they proudly showed off.

My first job out of design school was designing coolers and lunchbags for Arctic Zone, and that’s where I learned the art of creating spec drawings for people to work from across the world. Remember that old exercise from grade school where you had to write instructions on how to tie a shoe, which seemed easy at first but was actually quite difficult? Same kind of idea here. From a design standpoint, it really forces you to think through your idea because you can’t assume anything will just be understood. It takes a lot of practice and in the end I think it makes you a stronger designer.

Typically the design process for a new bag starts with me sending them a sketch of the concept, plus technical drawings with all the dimensions and material call-outs, and sometimes a rough prototype that I will have hacked together to illustrate the idea. From there, the sample makers make a prototype and send it to me, and the concept gets refined back and forth, using videos and Skype to go through trickier things.

This process works pretty well, but sometimes you gotta go over things in person. The factory we use makes high-end diaper bags, handbags and travel bags, but we are their first bike bags. During one of my visits last week, we brought in a bike to go through some of the functionality issues of a new design. Once they saw the bag on the bike, they immediately understood what I was talking about, and we had a good old-fashioned brainstorm about different ways to solve the problem. It was a lot of fun!

The cut-and-sew manufacturing industry in China is very mature, meaning that they have established infrastructure for making new products. Really, the only thing that limits you is your imagination, as there are suppliers and resources available to make pretty much anything you can think of. For a designer, it can feel like being a kid in a candy store. On my last day, we went to the fabric market, which is where all the fabric mills have a little kiosk showing their wares. This place is HUGE – you could probably spend the whole day walking it and not even cover the whole thing. There is fabric for every application, hardware, straps, zippers, embellishments…it’s pretty insane.

You just take a swatch card of fabrics you like, and follow up with them if you decide to buy it later.

Some of my finds: a cool geometric pattern (do you like it???) and some super soft faux leather.

Po Campo buys some of its materials “off the shelf” from the market because our manufacturing quantities are still too low to do custom runs for everything. For example, for some custom hardware, you have to buy 5,000+ pieces, which is more than we need, so we find “off the shelf” hardware at the market instead. But how do you know where the materials come from, and if they are high quality, if you aren’t making them yourself? Good question!

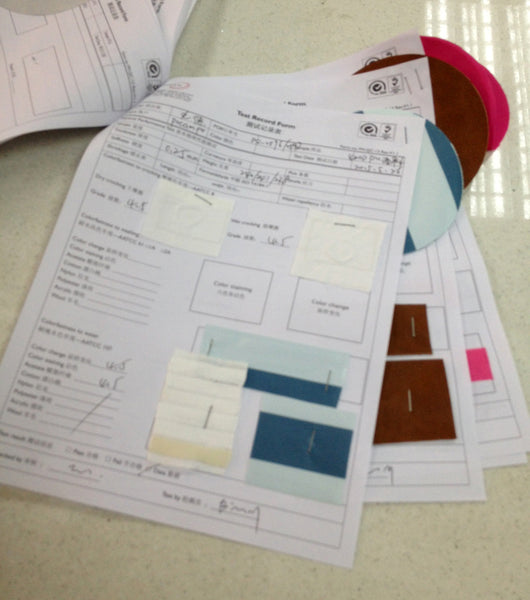

In addition to only working with companies that are ISO 9001 certified, our sourcing company provides another valuable service, and that is product and material testing. This includes testing for harmful chemicals in metals to fading in fabric to strength of stitches. All the materials in Po Campo bags are tested here to make sure they are durable enough and safe enough to meet our specifications.

Fabric and material testing lab

Testing sheets for Po Campo bags

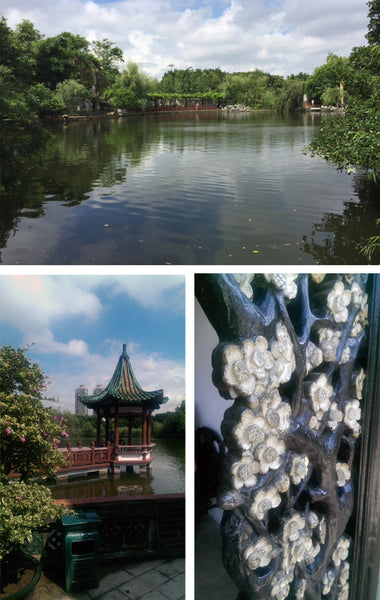

This was largely a work trip, but I managed to squeeze in some touristy stuff too. The annual Dragon Boat Festival, or Duanwu Festival, occurred while I was there, which is celebrated with dragon boat races and eating zongzi, sticky rice cakes stuffed with egg and wrapped in bamboo leaves. We went to a small town to watch the boat races, which was definitely off the beaten tourist path.

Watching the Dragon Boat Races and cheering for team yellow! Didn't know who they were, but one guy gave me a bottle of water when I walked by their team bench and won my loyalty.

The beautiful Dongguan KeYuan Park

You probably already know that I love city bike riding, but right up on the list of my favorite things to do is international travel. Experiencing other cultures helps me put things in perspective as I realize how different humans can be, but also how similar. I love figuring out how to communicate with people when you can’t rely on language or shared customs. The satisfaction (and joy, really) of being able to do this is only heightened when you are working, sharing ideas and figuring out how to make things. I love talking about the idea behind Po Campo, what is going on here in the bicycling renaissance in America, what things are important to our customers, and why, and working together to make awesome bags. It's pretty awesome.

Me sweating it out in Hong Kong

What questions do you have that I haven’t answered? Please leave in the comments below!

Comments

Our Daughter Daniella met you in a Bike Summit in DC in March. She sent us some of your photos of your trip in Dongguan and Hong Kong. Really enjoyed reading about your experiences. My wife Kitty is originally from Hong Kong and I missed traveling there but for the food!! Kitty is a Technical Designer for a company in Ohio. Even though I am not Chinese I surely do miss China very much!!!

Ernie Birch

I really enjoyed reading this, Maria. All the hard work and pains taken really show in your finished products which are still unique. I’m a member of a Glasgow bike group called Belles on Bikes and women are always asking about my Po Campo gear, so I make sure to sing your praises.

Fascinating!! Thanks for sharing.